Vietnam’s warehouse management systems (WMS) have undergone significant changes over the years. This development is driven by a combination of economic growth, globalization, and technological advancements. As the country has rapidly transformed into a manufacturing and logistics hub for the region, the demand for modern and efficient warehouses has increased.

This increase in demand has led to the development of new warehouse models, such as e-commerce fulfillment centers, automated facilities, and cold storage units. However, there are still challenges in terms of infrastructure, technology adoption, and labor skills, as well as environmental sustainability. This report will provide an overview of the current state of Vietnam’s warehouse system, the most common warehouse management systems and the companies that provide them.

Traditional Warehouse Management System Vs. Smart Warehouse Management System in Vietnam

Traditional Warehouse Management System

A traditional warehouse management system with mainly manual labor typically involves the use of human workers to manage and operate all aspects of the warehouse. The following are the typical components of such a system:

- Receiving: The process of receiving goods into the warehouse typically involves manual unloading of trucks, manual checking of delivery notes and packing slips, and manually recording and updating inventory records.

- Storage: Once the laborers receive goods, they manually store them in designated areas within the warehouse. This involves manual labeling and organization of products to facilitate easy retrieval and movement of goods.

- Picking: When customers make an order, workers manually locate the products within the warehouse and pick them for shipment. This involves identifying the correct product, verifying the product’s quality, and packaging the product for shipment.

- Shipping: Once the workers pick up the products, they manually load them onto trucks for delivery to the customer. This involves verifying that the correct products have been loaded and completing shipping documents.

- Inventory management: The manual management of inventory involves tracking the movement of products in and out of the warehouse, reconciling discrepancies, and generating reports to provide insight into inventory levels.

- Labor management: The manual labor management process involves managing the scheduling, tracking, and supervision of workers, including training and performance monitoring.

Overall, a traditional warehouse management system with mainly manual labor is labor-intensive. This type of warehouse can be prone to errors due to the manual nature of the processes.

Smart Warehouse Management System

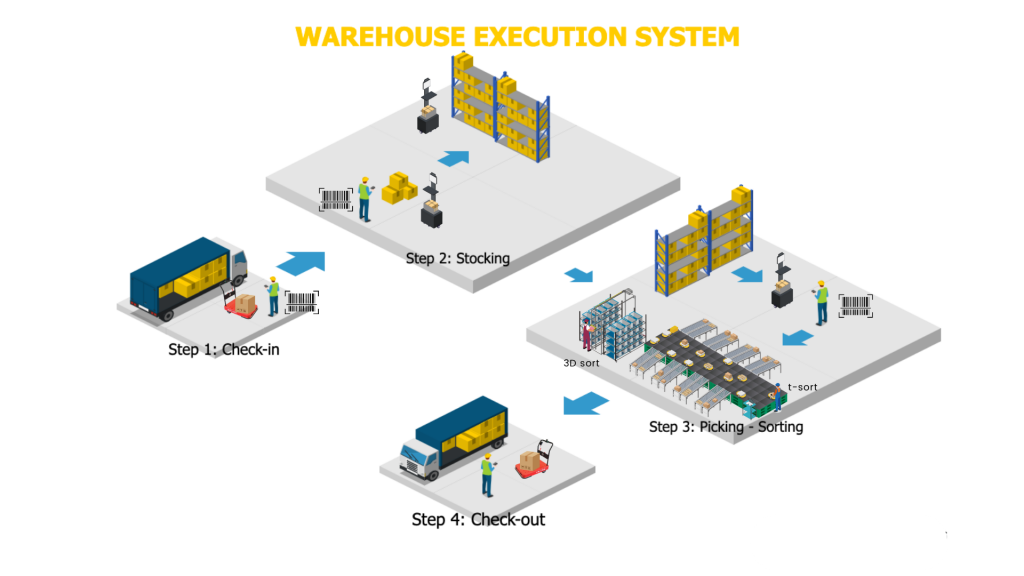

An automatic warehouse management system with robots doing the picking, sorting, and categorizing processes is a modern solution. This process can improve warehouse efficiency, accuracy, and safety. Here’s how such a system is different from a traditional system:

- Receiving: As the goods arrive, scanners scan them with QR codes to ensure the correct inventory data is updated automatically in the system. Robots then unload and transport the goods to the designated storage areas.

- Storage: Robots handle the storage of the goods by organizing them in the warehouse according to predefined criteria, such as product type, shelf life, or order frequency. QR codes are able to track the location of each product in real-time.

- Picking: When system recognizes an order, a robot picks the requested products from their storage location using sensors and scanners to ensure the correct product is retrieved. Once picked, the robot may package the products and prepare them for shipment.

- Shipping: A robot may handle the loading of products onto the delivery vehicle, with each product scanned and checked for accuracy. This process ensures that the correct products are loaded onto the correct vehicle and delivered to the correct destination.

- Inventory management: An automatic warehouse management system with QR codes ensures that inventory records are updated in real-time, which helps to prevent discrepancies and inaccuracies. Robots are also used to conduct regular stock checks and report any discrepancies to the system.

- Labor management: With the use of robots and automation, there is a significantly less demand for labour requirements. However, skilled technicians and engineers need to maintain and repair the system.

A smart warehouse management system with robots, QR scanners, and minimized labor work can greatly increase warehouse efficiency and accuracy while reducing the risk of errors and injuries. This type of system can also help to reduce labor costs and improve overall productivity.

Current Picture of Warehouse Management Systems in Vietnam

The potential market for WMS

In Vietnam, there are currently approximately 550 companies. These range from large corporations such as Shopee Vietnam and Tiki to medium-sized companies like Binh Duong Logistics JSC. All corporations utilize warehouses and may employee a professional management system.

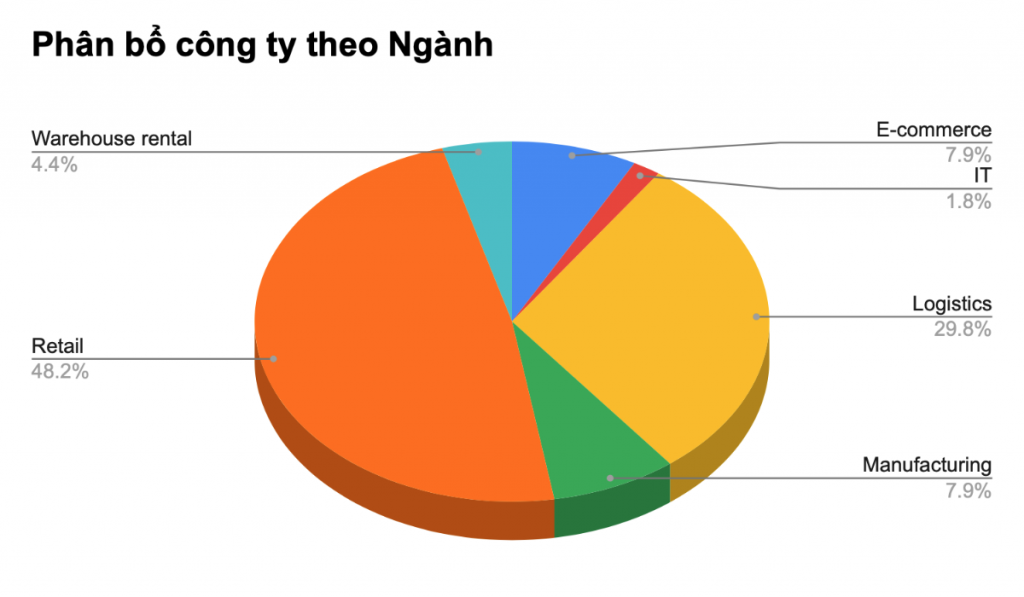

According to the provided data, most companies in this dataset belong to the retail sector. This suggests that retail is a highly potential industry for warehouses, with many businesses vying for market share.

The logistics sector also appears to be significant, with 163 companies operating within this space. This highlights the importance of logistics in the supply chain. The reason is because companies must manage the movement of goods and products from manufacturing sites to retail stores or e-commerce fulfillment centers. E-commerce and manufacturing follow, with 40 companies each, indicating a relatively smaller market share compared to the former two sectors.

Finally, the IT and warehouse rental sectors have the lowest number of companies, with only 10 and 25 companies, respectively. This suggests that these industries may be more niche or specialized, with fewer players in the market.

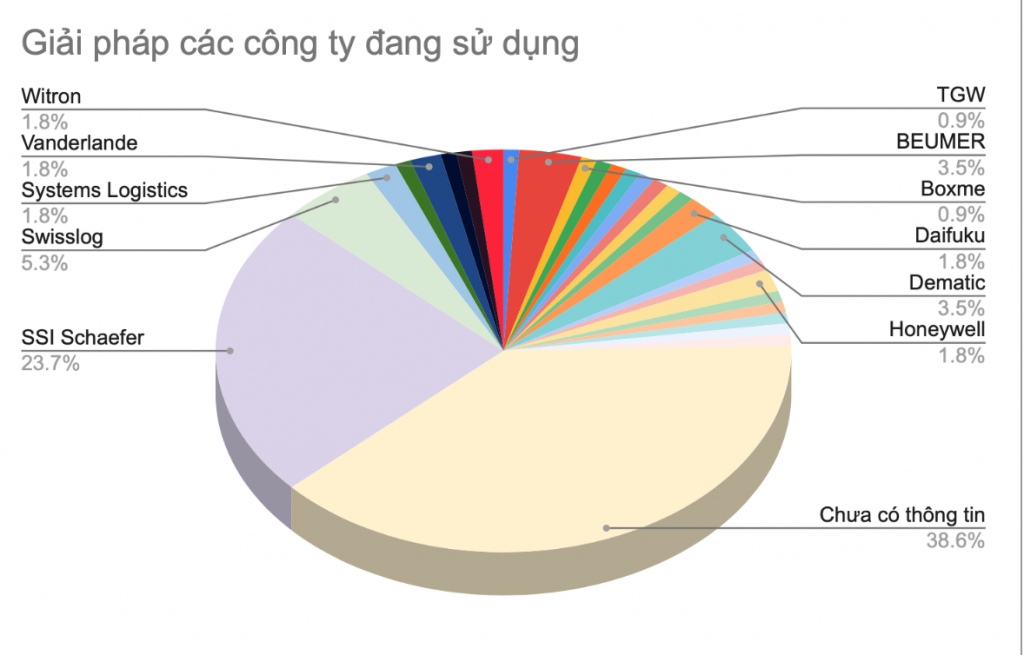

Current Solutions Employed In The Industry

A majority of companies that are running warehouses have already employed a professional system to manage all aspect of a warehouse

What’s in it for Medium and Small-sized companies that want to build their own WMS?

Small enterprises can also have the potential to build Warehouse Management Systems (WMS) by leveraging available technology and resources. The advancements in technology and availability of cloud-based solutions have made it easier for small businesses to build and deploy software systems at a lower cost.

Some potential advantages of building a WMS for small enterprises include:

- Customization: Small businesses may require specific features or functionalities in their WMS that are not available in off-the-shelf solutions. By building their own WMS, they can customize it to meet their specific needs.

- Cost savings: Building a WMS in-house can be more cost-effective than purchasing a pre-built solution, especially for small businesses with limited budgets. It can also be more affordable to maintain and update in the long run.

- Competitive advantage: By having a WMS which tailors to business needs, small enterprises can gain a competitive advantage in their industry.

- Scalability: A custom-built WMS can scale up or down based on the changing needs of the business, making it a more flexible solution than an off-the-shelf system.

However, building a WMS can be a complex and time-consuming process that requires specialized skills and expertise. Small enterprises may need to invest in hiring or contracting software developers, project managers, and other experts to ensure the success of their WMS project. Additionally, maintaining and updating a custom-built WMS can also be a long-term commitment that requires ongoing resources and support.

HOPEE is a leading company in building website and mobile applications, as well as other softwares. We pride ourselves in delivering excellent services and reliable products

Read more of our success stories here.